Process Capability

Process capability

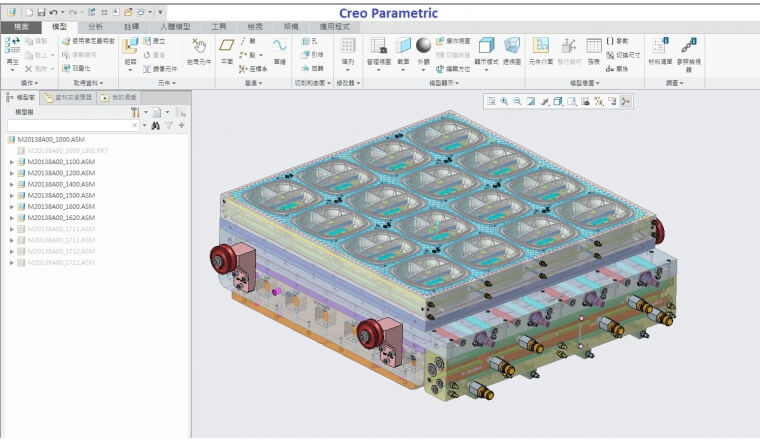

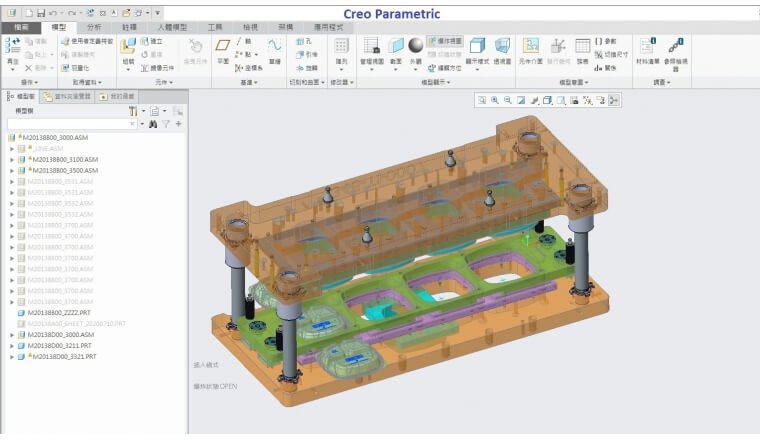

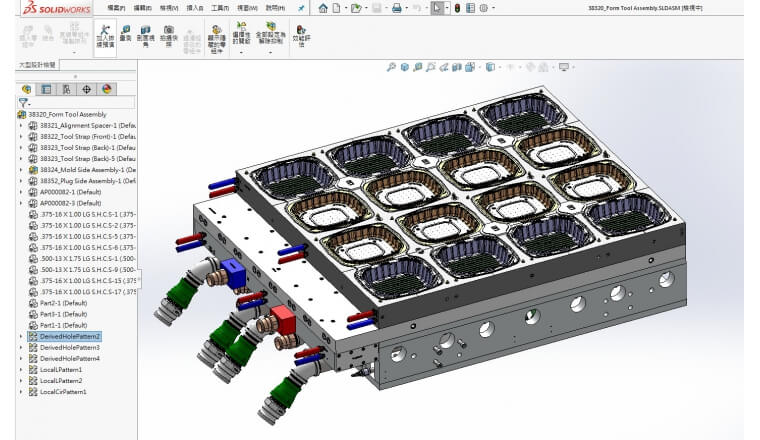

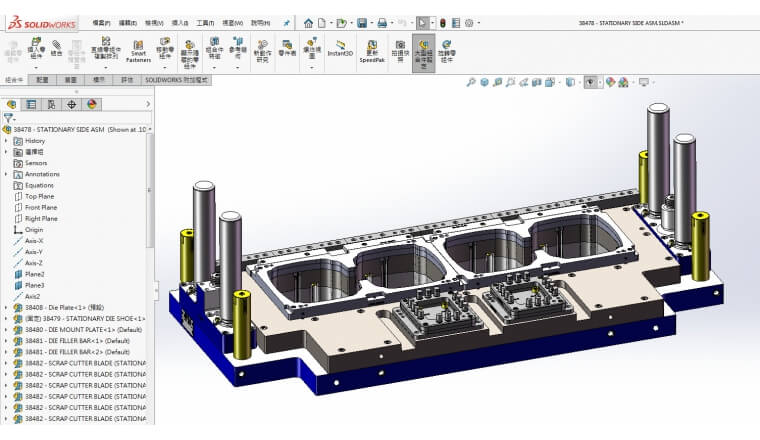

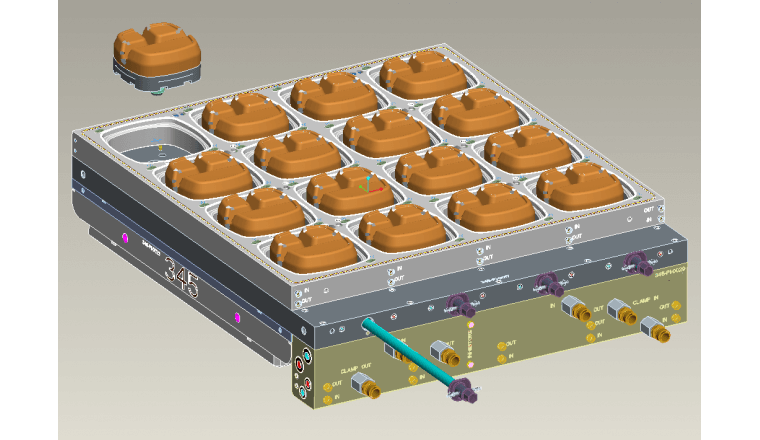

Thermoforming mold design

Using CAD softwares, Solidworks, and Creo, to build 3D model. And HongZu will analyze the 3D model on mold structure optimization and cooling system efficiency.

(more about thermoforming dies and tools design)

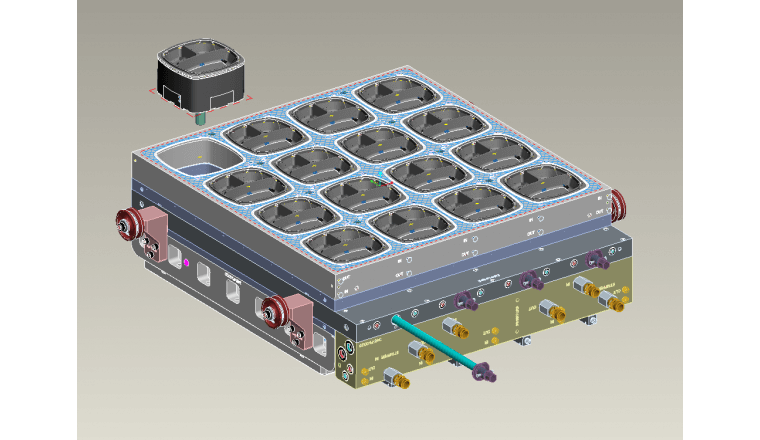

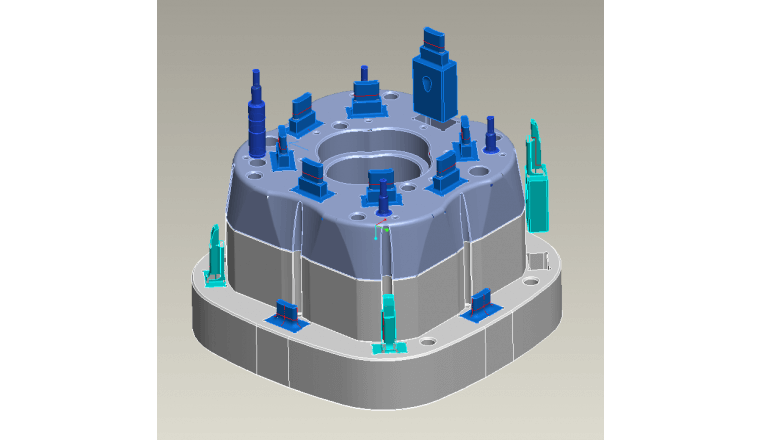

Cavity quick-change system

In order to fulfill the massive requirements on reducing mold setup time and increasing the machine efficiency. HongZu has developed a cavity quick-change system to our customers. Which allows them to rapidly change cavities and save labor force.

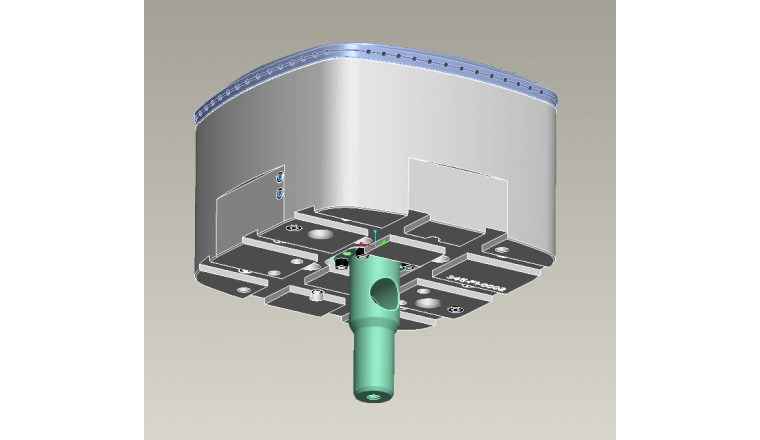

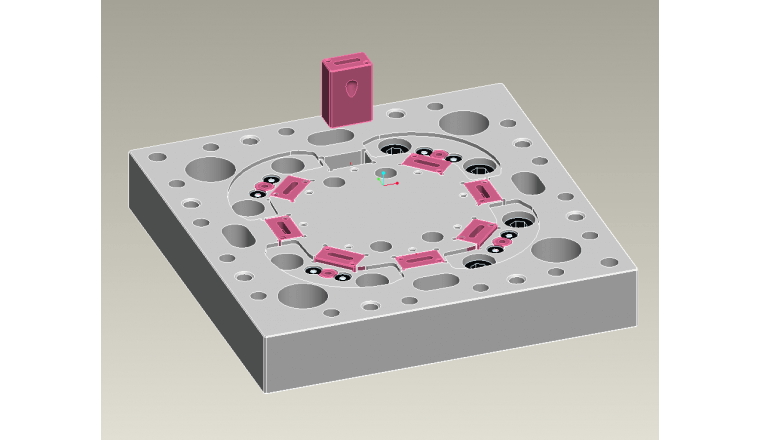

Punch and Die quick-change system

It's a state-of-art mold technology allows our customers to replace their pre-punch die and punch without uninstalling the mold and even unscrewing any bolts.

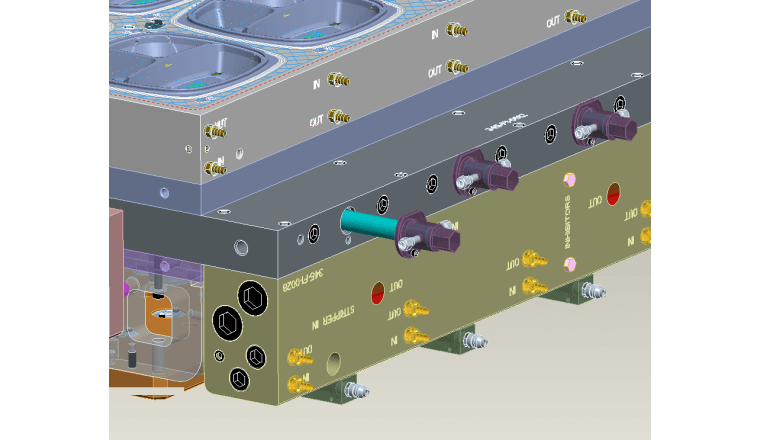

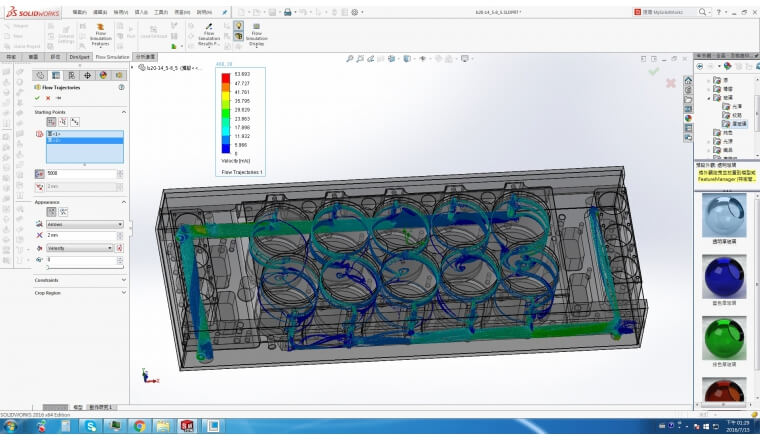

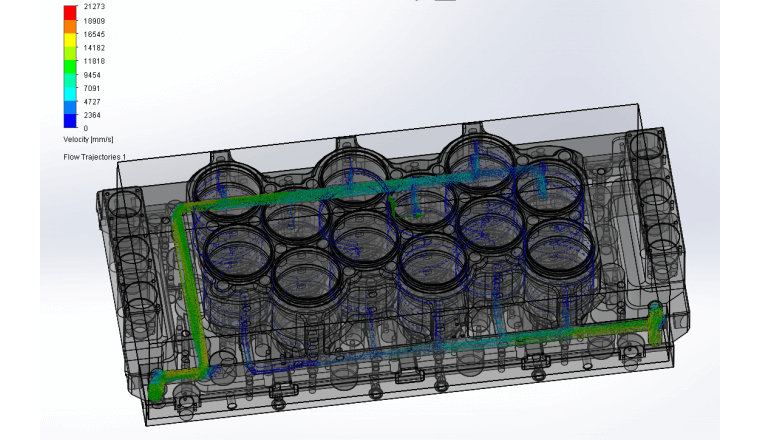

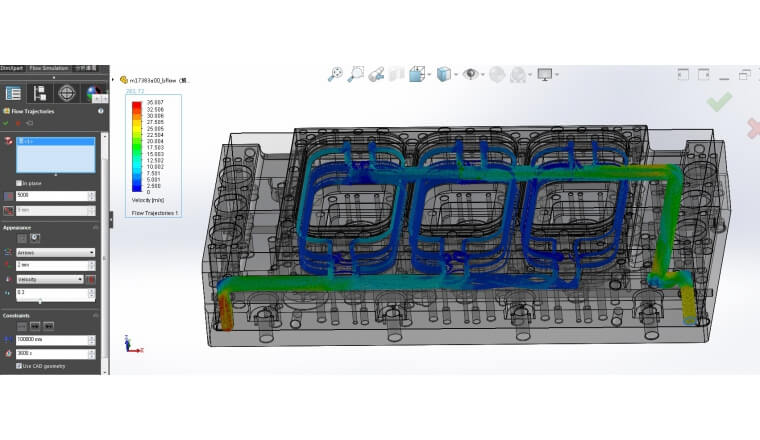

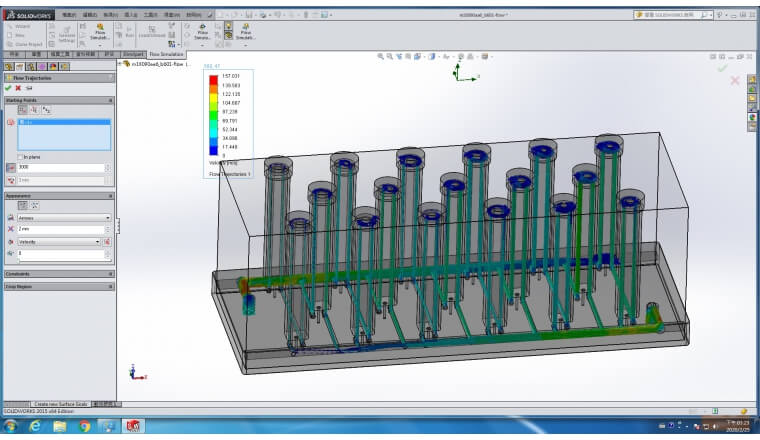

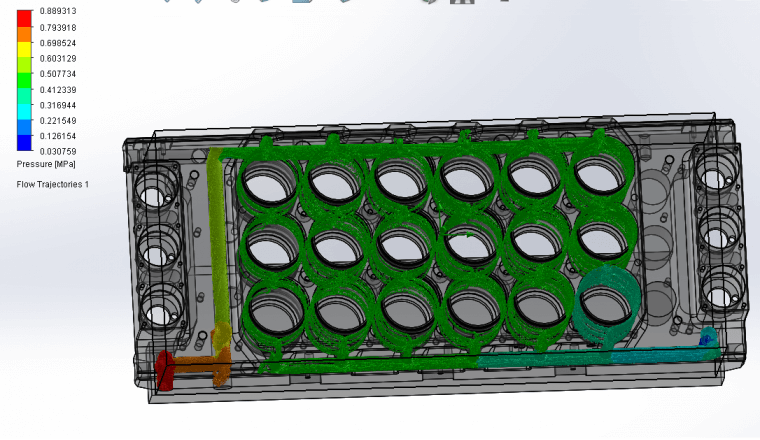

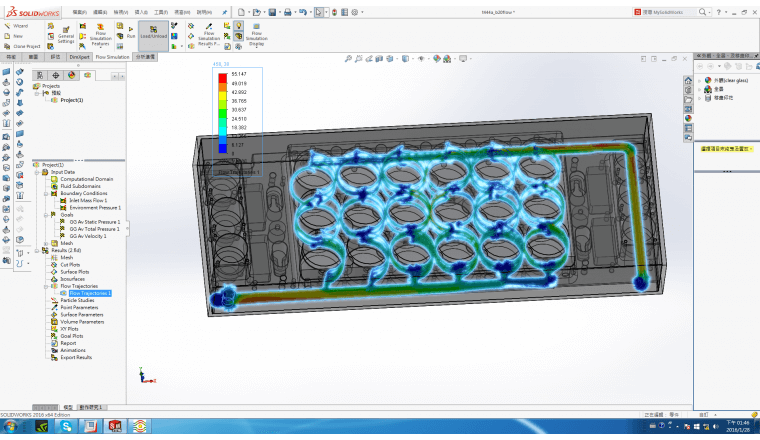

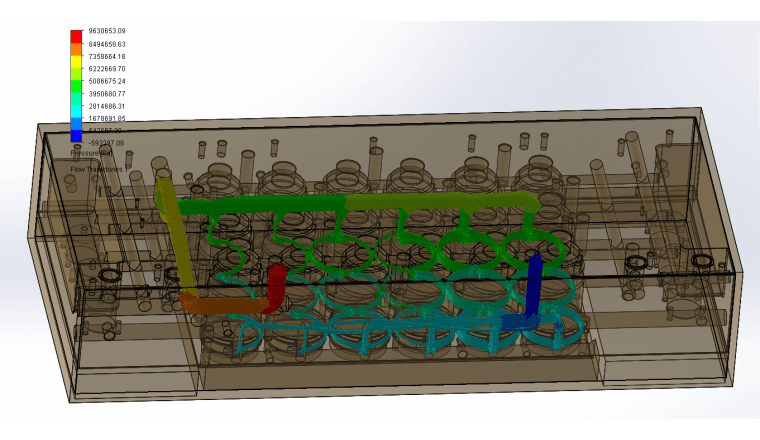

Mold flow analysis

Cooling system is a core technique in mold efficiency. In order to better predict and calculate the mold flow system prior to practical manufacturing, HongZu design team apply the CFD(computational fluid dynamics) technology to every mold we built. Through the mold flow simulation, we can not only optimize the mold flow routes but also increasing total mold efficiency.

Components standardization

Lead time is one of the thing that our customers care a lot. With a view to not keep our customers on hold, HongZu has standardized those most frequent used components in to HongZu spec. So, whenever our clients order those components, we will be able to deliver those parts promptly.