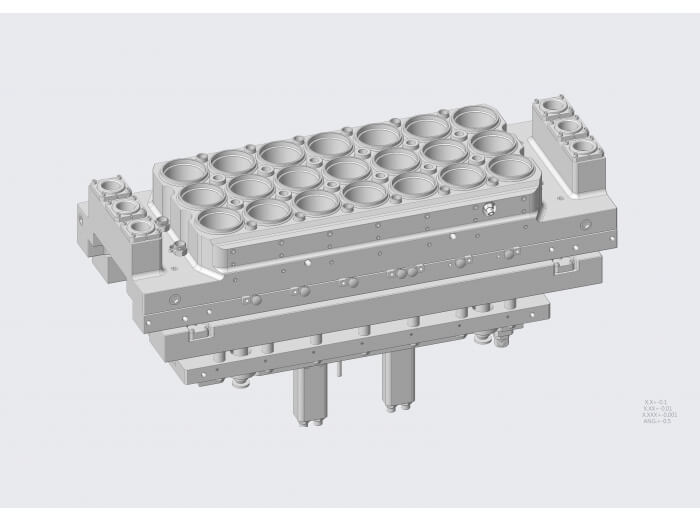

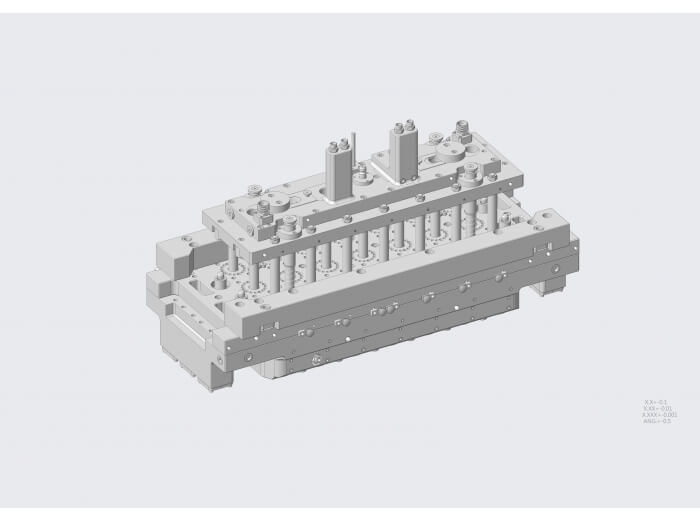

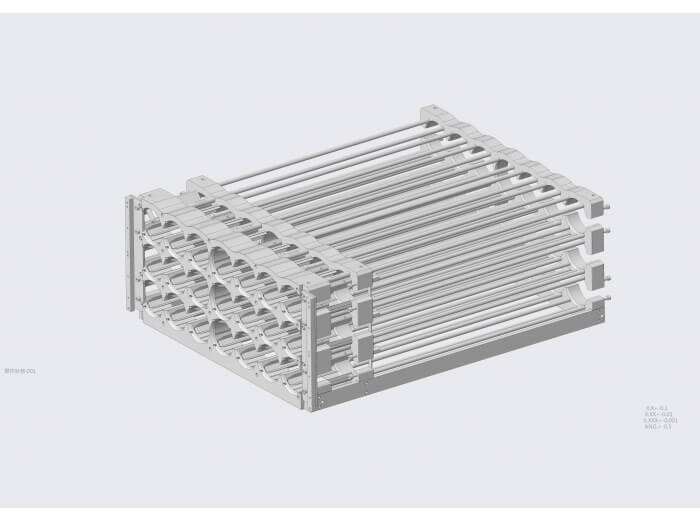

In-mold cutting

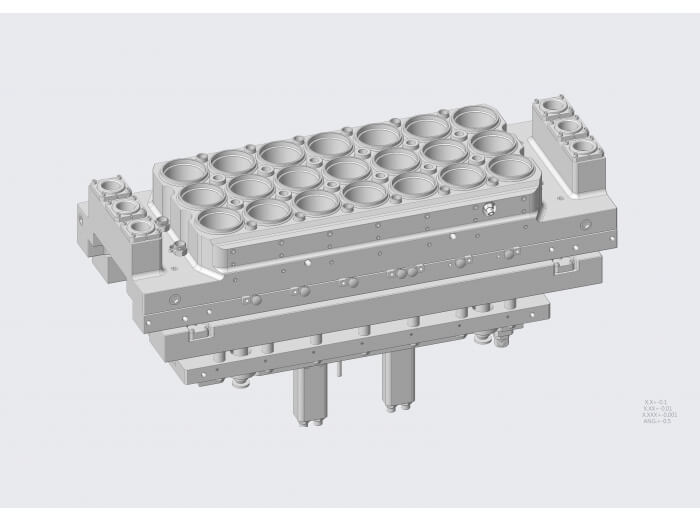

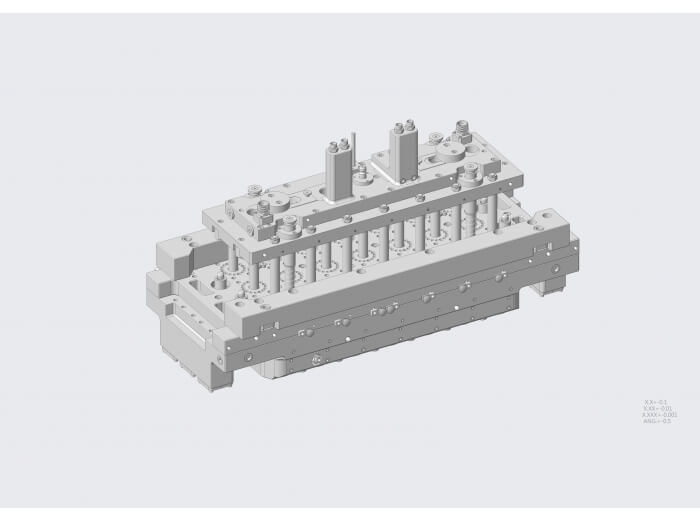

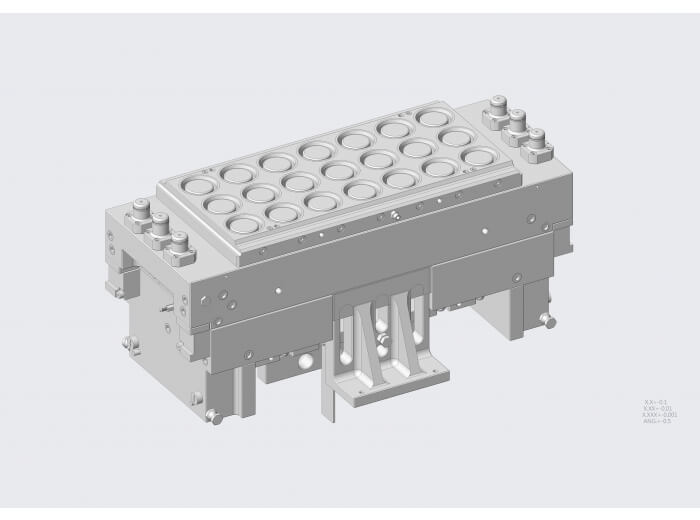

In-mold cutting is a widely used technology in thermoforming production. It can form and cut simultaneously, with fast cutting speed and precise dimensions, resulting in high product quality. In-mold cutting is mainly used for producing thermoformed cups, lids, and products with high requirements for consistent cutting edges.

Features of In-mold cutting:

• Simultaneous forming and cutting, fast cutting speed, and precise dimensions.

• Consistent cutting edges and high product quality.

• Can reduce production processes and costs.

• Can improve product quality and reduce product defect rates.

• Suitable for companies and factories that produce large quantities of thermoformed products.

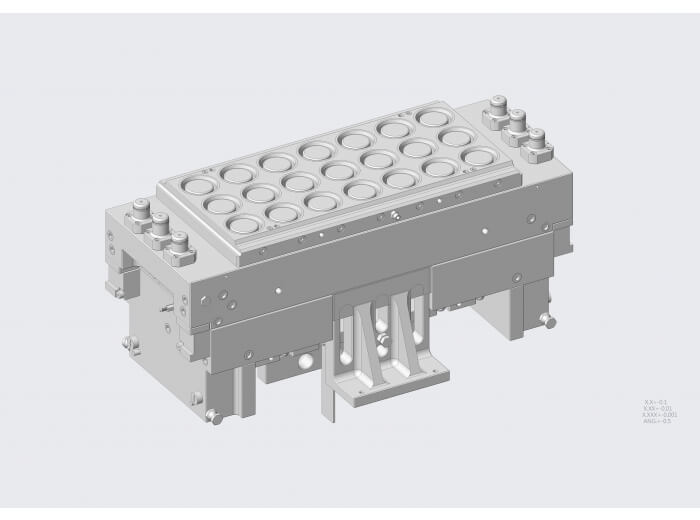

The following products are suitable for In-mold cutting thermoforming mold:

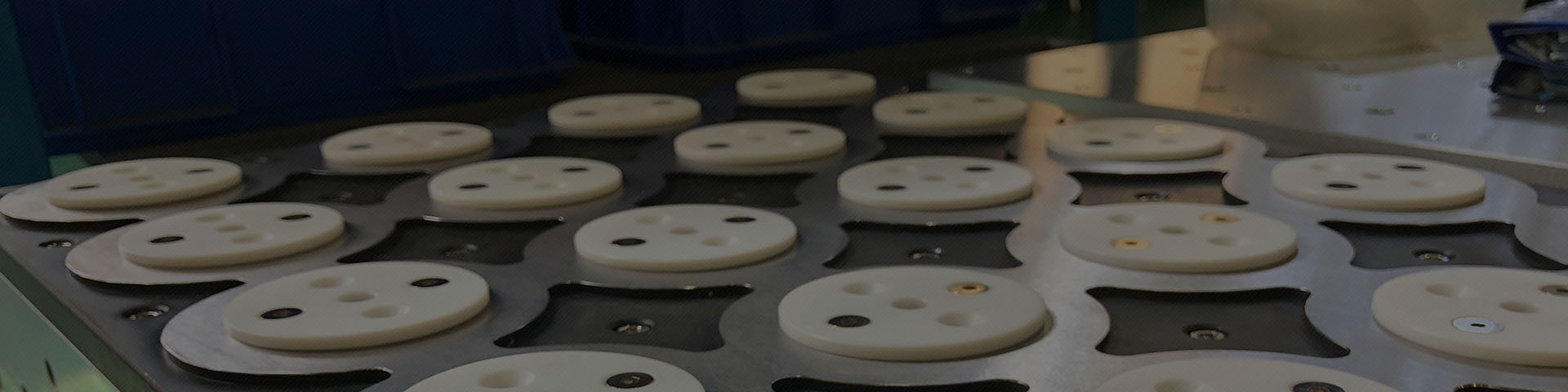

• Thermoformed cups, such as disposable coffee cups and tea cups.

• Thermoformed lids, such as beverage bottle caps and can lids.

• Thermoformed containers, such as food packaging boxes and gift boxes.

• Thermoformed trays, such as cutlery trays and fruit trays.

• Other thermoformed products, such as bowls and cutlery.

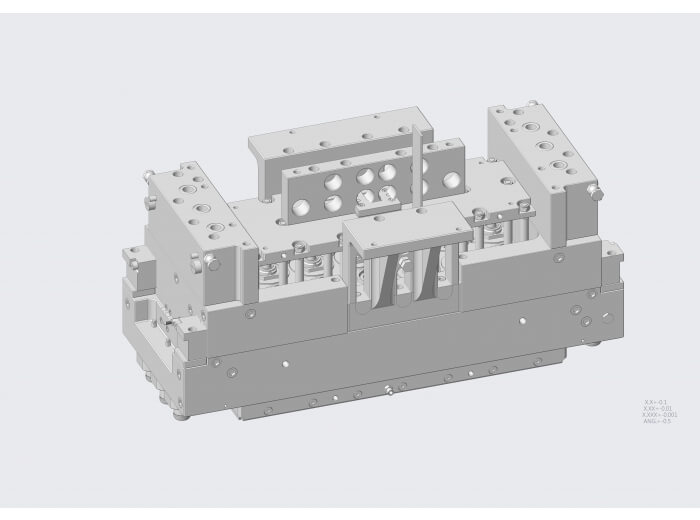

At HongZu, we are committed to providing customers with high-quality In-mold cutting products and services, as well as professional technical support and problem-solving services to ensure smooth production and achieve a win-win situation.

- Product Category

- Applicable machine

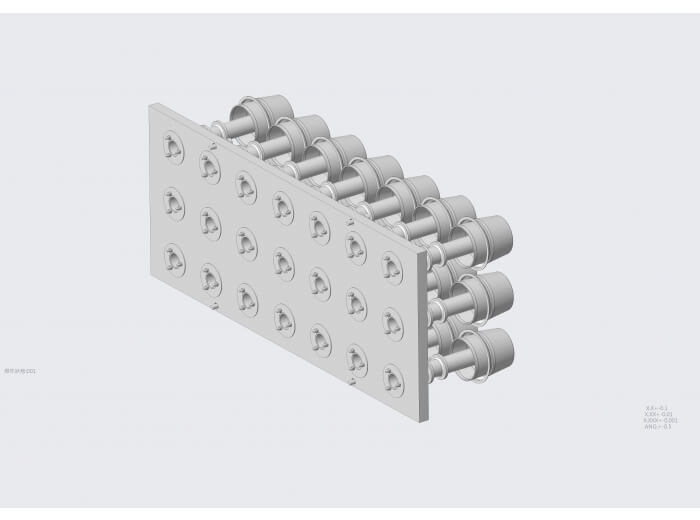

ILLIG - RDM 70K / RDM 75K / RDM 75Kc

WM -Twist 700 / FT 700 / FT 900

KIEFEL- KTR 4 / KTR 5 / KTR 6

GABLER - M92 / M92XL / M98

AMUT - AMP630 / AMP850S-GP